Repair Techniques

- First Online: 20 May 2020

Cite this chapter

- Jorge de Brito 5 ,

- Clara Pereira 6 ,

- José D. Silvestre 7 &

- Inês Flores-Colen 8

480 Accesses

1 Citations

Since the use of classification lists is advantageous when using building inspection systems, including a classification list of repair techniques in those systems assists the surveyor during inspection procedures. Such list, for the building envelope’s inspection, should include techniques for repairs on the surface of the cladding or in the cladding system, as well as procedures to make changes in the bearing structure or in the substrate and in singular points of the building envelope. Repair techniques should be used within maintenance plans as corrective or preventive work, including regular maintenance procedures. According to the classification of repair techniques and that of defects, the most adequate repair techniques should be defined in a correlation matrix associating defects with repair techniques taking the affected building element or material into account. Some techniques may be used to repair a specific defect or eliminate its causes without any restrictions (correlation index 2), but others may have some constraints (correlation index 1).

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

- Durable hardcover edition

Tax calculation will be finalised at checkout

Purchases are for personal use only

Institutional subscriptions

ACI Committee 224 (2007) Causes, evaluation, and repair of cracks in concrete structures ACI 224.1R-07. Farmington Hills, MI USA

Google Scholar

Amaro B, Saraiva D, de Brito J, Flores-Colen I (2014) Statistical survey of the pathology, diagnosis and rehabilitation of ETICS in walls. J Civ Eng Manag 20:511–526. https://doi.org/10.3846/13923730.2013.801923

Article Google Scholar

Amaro B, Saraiva D, de Brito J, Flores-Colen I (2013) Inspection and diagnosis system of ETICS on walls. Constr Build Mater 47:1257–1267. https://doi.org/10.1016/j.conbuildmat.2013.06.024

Andrady AL, Hamid SH, Hu X, Torikai A (1998) Effects of increased solar ultraviolet radiation on materials. J Photochem Photobiol B Biol 46:96–103. https://doi.org/10.1016/S1011-1344(98)00188-2

Arditi D, Nawakorawit M (1999) Issues in building maintenance: property managers’ perspective. J Archit Eng 5:117–132

Ashurst J (1998) Methods of repairing and consolidating stone buildings. In: Ashurst J, Dimes FG (eds) Conservation of building and decorative stone, vol 2, 2nd edn. Butterworth-Heinemann, Oxford, UK, pp 1–54

Ashurst J, Ashurst N (1988a) Practical building conservation. English Heritage technical handbook volume 1: Stone masonry. Gower Technical Press, Hants, UK

Ashurst J, Ashurst N (1988b) Practical building conservation. English Heritage technical handbook volume 5: Wood, glass and resins. Gower Technical Press, Hants, UK

ASTM International (2013) ASTM E1857-91(2013) e1. Standard guide for selection of cleaning techniques for masonry, concrete, and stucco surfaces. ASTM International, West Conshohocken, PA USA

Auel TE (2005) Cleaning EIFS. An emerging cleaning market. Clean. Times 14–18

Austin-Smith: Lord LLP (2007) Conservation area maintenance guide. John Finnie Street and Bank Street, Kilmarnock. East Ayrshire Council, East Ayrshire, Scotland

Branco FA, de Brito J (2004) Handbook of concrete bridge management. ASCE Press, Reston, VA USA

Book Google Scholar

Bureau Veritas (1993) Guide Veritas du bâtiment. Tome 4: Gestion technique du patrimoine, réhabilitation et maintenance (Veritas building guide. Volume 4: Technical management of heritage, rehabilitation and maintenance). Le Moniteur, Paris, France

California Energy Commission (2005) Technical brief—residential roofs: cool colors, cool gaps. State of California Energy Commission, Sacramento, CA USA

Campanella C, Mateus JM (2003) Obras de conservação e restauroarquitectónico: condiçõestécnicasespeciais (Conservation and architectural restoration works: special technical conditions). Câmara Municipal de Lisboa, Lisboa, Portugal

Carvalho C, de Brito J, Flores-Colen I, Pereira C (2018) Inspection, diagnosis, and rehabilitation system for vinyl and linoleum floorings in health infrastructures. J Perform Constr Facil 32:04018078. https://doi.org/10.1061/(ASCE)CF.1943-5509.0001229

CCAA T57 (2006) Guide to off-form concrete finishes. Cement Concrete & Aggregates Australia, Sydney, Australia

Centro Tecnológico da Cerâmica e do Vidro (1998) Manual de aplicação de telhas cerâmicas (Application guide of ceramic roof tiles). Associação Portuguesa dos Industriais da Cerâmica de Construção, Coimbra, Portugal

Chapman S (2000) Laser technology for graffiti removal. J Cult Herit 1:S75–S78. https://doi.org/10.1016/S1296-2074(00)00153-9

CIB W86 (1993) Building pathology: a state-of-the-art report. International Council for Research and Innovation in Building and Construction, Delft, The Netherlands

Conceição J, Poça B, de Brito J et al (2017) Inspection, diagnosis, and rehabilitation system for flat roofs. J Perform Constr Facil 31:04017100. https://doi.org/10.1061/(ASCE)CF.1943-5509.0001094

da Silva C, Coelho F, de Brito J et al (2017) Inspection, diagnosis, and repair system for architectural concrete surfaces. J Perform Constr Facil 31:04017035. https://doi.org/10.1061/(ASCE)CF.1943-5509.0001034

de Brito J, Branco FA, Ibañez M (1994) Knowledge-based concrete bridge inspection system. Concr Int 16:29–63

de Brito J, Flores-Colen I (2015) Gypsumplasters. In: Gonçalves MC, Margarido F (eds) Materials for construction and civil engineering. Springer, Switzerland, pp 123–184

Delgado A, de Brito J, Silvestre JD (2013) Inspection and diagnosis system for wood flooring. J Perform Constr Facil 27:564–574. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000342

Douglas J, Noy EA (2011) Building surveys and reports, 4th edn. Wiley-Blackwell, Chichester, United Kingdom

Dow Corning (2002) EIFS restoration guide. Dow Corning, Midland, MI USA

Emmons PH (1994) Concrete repair and maintenance illustrated: problem analysis, repair strategy, techniques. R. S. Means Company Inc., Kingston, MA, USA

Esteves C, Ahmed H, Flores-Colen I, Veiga R (2019) The influence of hydrophobic protection on building exterior claddings. J Coatings Technol Res. https://doi.org/10.1007/s11998-019-00220-7

European Organisation for Technical Approvals (2013) ETAG 004: Guideline for European technical approval of external thermal insulation composite systems (ETICS) with rendering. European Organisation for Technical Approvals, Brussels, Belgium

Exterior Insulation Finish Systems Council of Canada (2007) Understanding efflorescence. Technical bulletin 4. Version 1.2. http://eifscouncil.org/wp-content/uploads/2012/02/Tech-Efflorescence-V1_2.pdf . Accessed 17 Feb 2019

Fernandes C, de Brito J, Cruz CO (2016) Thermal retrofitting of façades: architectural integration of ETICS. J Perform Constr Facil 30:06015002. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000770

Figliuzzi G, Vazquez E, Nobrega J et al (2018) Cost and productivity of self-levelling underlayment compared to traditional methods. In: Villegas L, Lombillo I, Blanco H, Boffill Y (eds) Rehabend construction pathology, rehabilitation technology and heritage management. University of Cantabria, University of Extremadura, Cáceres, Spain, pp 1227–1234

Flores-Colen I, de Brito J (2010) Discussion of proactive maintenance strategies in façades’ coatings of social housing. J Build Apprais 5:223–240. https://doi.org/10.1057/jba.2009.21

Flores-Colen I, de Brito J, de Freitas VP (2008) Stains in facades’ rendering—diagnosis and maintenance techniques’ classification. Constr Build Mater 22:211–221. https://doi.org/10.1016/j.conbuildmat.2006.08.023

Gaião C, de Brito J, Silvestre J (2011) Inspection and diagnosis of gypsum plasterboard walls. J Perform Constr Facil 25:172–180. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000149

Garcez N, Lopes N, de Brito J, Silvestre J (2012) System of inspection, diagnosis and repair of external claddings of pitched roofs. Constr Build Mater 35:1034–1044. https://doi.org/10.1016/j.conbuildmat.2012.06.047

Garcia J, de Brito J (2008) Inspection and diagnosis of epoxy resin industrial floor coatings. J Mater Civ Eng 20:128–136. https://doi.org/10.10617/(ASCE)0899-1561(2008)20:2(128)

Glover P (2009) Building surveys, 7th edn. Butterworth-Heinemann, Oxford, United Kingdom

Goldberg RP (2011) Direct adhered ceramic tile, stone, masonry veneer, and thin brick facades—technical manual, 2nd edn. Laticrete—Innovative Tile and Stone Installation Systems, North Bethany, CT USA

Grimmer AE (1988) Keeping it clean: removing exterior dirt, paint, stains and graffiti from historic masonry buildings. U.S. Department of the Interior, National Park Service Cultural Resources, Heritage Preservation Services, Washington DC, USA

Grimmer AE, Konrad KA (1996) Preserving historic ceramic tile floors. U.S. Department of the Interior, National Park Service Cultural Resources, Heritage Preservation Services, Washington DC, USA

Harrison HW, Trotman PM, Saunders GK (2009) Roofs and roofing: performance, diagnosis, maintenance, repair and the avoidance of defects, 3rd edn. IHS Bre Press, Watford, UK

Hollaway L (2010) Polymers. In: Domone P, Illston J (eds) Construction materials: their nature and behaviour, 4th edn. Spon Press, London, UK, pp 305–315

Houghton-Evans RW (2005) Well Built? A forensic approach to the prevention, diagnosis and cure of building defects. RIBA Enterprises, London, United Kingdom

Janz M, Byfors K, Johansson L (2004) Surface treatments. In: REHABCON IPS-2000-00063 (ed) REHABCON strategy for maintenance and rehabilitation in concrete structures. DG Enterprise of the European Commission, Stockholm, Sweden

Joti S, Mitra K (2018) Seismic retrofitting strategy of the historic monasteries in Sikkim, India, after 2011 M 6.9 Sikkim earthquake. In: Villegas L, Lombillo I, Blanco H, Boffill Y (eds) Rehabend construction pathology, rehabilitation technology and heritage management. University of Cantabria, University of Extremadura, Cáceres, Spain, pp 1898–1904

Kenney AR, Freedman S, Shilstone Jr. JM (2008) Architectural concrete. In: Nawy EG (ed) Concrete construction engineering handbook, 2nd edn. CRC Press, Boca Raton, FL USA, pp 30-1–30-74

Künzel HHM, Künzel HHM, Sedlbauer K (2006) Long-term performance of external thermal insulation systems (ETICS). ACTA Archit 5:11–24

Lawson J (2012) Roof drainage “Not my problem… Maybe.” In: Structural engineers association of California 2012 Convention. Santa Fe, NM USA, pp 136–151

Lerma C, Blasco V, Mas Á et al (2016) Basis of stone panel pathology and application of infrared thermography in the pathology study of back-ventilated façades with stone panels. In: Delgado JMPQ (ed) Case studies of building pathology in cultural heritage. Springer, Singapore

Matziaris K, Stefanidou M, Karagiannis G (2011) Impregnation and superhydrophobicity of coated porous low-fired clay building materials. Prog Org Coatings 72:181–192. https://doi.org/10.1016/j.porgcoat.2011.03.012

Moura A, Flores-Colen I, de Brito J (2016) Study of the effect of three anti-graffiti products on the physical properties of different substrates. Constr Build Mater 107:157–164. https://doi.org/10.1016/j.conbuildmat.2015.12.181

Moura A, Flores-Colen I, de Brito J, Dionisio A (2017) Study of the cleaning effectiveness of limestone and lime-based mortar substrates protected with anti-graffiti products. J Cult Herit 24:31–44. https://doi.org/10.1016/j.culher.2016.04.004

National Precast Concrete Association (2013) Precast concrete architectural repair guide. National Precast Concrete Association, Carmel, IN USA

National Roofing Contractors Association (1989) Handbook of accepted roofing knowledge. National Roofing Contractors Association, Rosemont, IL USA

Neto N, de Brito J (2011) Inspection and defect diagnosis system for natural stone cladding. J Mater Civ Eng 23:1433–1443. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000314

Newman J, Choo BS (2003) Advanced concrete technology: processes. Butterworth-Heinemann, Oxford, United Kingdom

Pattanaik SC (2011) Repair of active cracks of concrete structures with a flexible polyurethane sealant for controlled movement. In: AMAS-2011. Puducherry, India

Pereira A, Palha F, de Brito J, Silvestre JD (2011) Inspection and diagnosis system for gypsum plasters in partition walls and ceilings. Constr Build Mater 25:2146–2156. https://doi.org/10.1016/j.conbuildmat.2010.11.015

Pires R, de Brito J, Amaro B (2015) Inspection, diagnosis, and rehabilitation system of painted rendered façades. J Perform Constr Facil 29:04014062. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000534

Precast/Prestressed Concrete Institute (2007) Architectural precast concrete, 3rd edn. PCI (Precast/Prestressed Concrete Institute), Chicago, IL USA

Rauf A, Crawford RH (2015) The effect of building and material service life on the life cycle embodied energy of an apartment building. In: Crawford RH, Stephan A (eds) Living and learning: research for a better built environment: 49th international conference of the architectural science association. The Architectural Science Association and The University of Melbourne, Melbourne, Australia, pp 413–422

Richardson BA (1980) Remedial treatment of buildings. The Construction Press, Lancaster, United Kingdom

Richardson BA (2001) Defects and deterioration in buildings, 2nd edn. Spon Press, London, United Kingdom

Rottmann O, Höfer P (1989) VorrichtungzurVerhinderung von Pflanzenwuchs auf Dachflächen (Device for preventing plant growth on roof surfaces). DE 3913030 A1

Sá G, Sá J, de Brito J, Amaro B (2014) Inspection and diagnosis system for rendered walls. Int J Civ Eng 12:279–290

Santos A, Vicente M, de Brito J et al (2017) Inspection, diagnosis, and rehabilitation system of door and window frames. J Perform Constr Facil 31:04016118. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000992

Seeley IH (1987) Building maintenance, 2nd edn. Palgrave, Hampshire, United Kingdom

Silvestre JD, de Brito J (2011) Ceramic tiling in building façades: inspection and pathological characterization using an expert system. Constr Build Mater 25:1560–1571. https://doi.org/10.1016/j.conbuildmat.2010.09.039

Silvestre JD, de Brito J (2010) Inspection and repair of ceramic tiling within a building management system. J Mater Civ Eng 22:39–48. https://doi.org/10.1061/(ASCE)0899-1561(2010)22:1(39)

Silvestre JD, de Brito J (2009) Ceramic tiling inspection system. Constr Build Mater 23:653–668. https://doi.org/10.1016/j.conbuildmat.2008.02.007

Stahl FA (1984) A guide to the maintenance, repair, and alteration of historic buildings. Van Nostrand Reinhold Company Inc., New York, USA

State Heritage Office (2012) Cleaning stone masonry. State Heritage Office, Government of Western Australia, Perth, Australia

Sto Corp. StoTherm® EIFS reference guide: repair and maintenance. Sto Corp., Atlanta, GA USA

Sulakatko V, Lill I, Witt E (2006) Methodological framework to assess the significance of external thermal insulation composite system (ETICS) on-site activities. Energy Procedia 96:446–454. https://doi.org/10.1016/j.egypro.2016.09.176

Technical Conservation Research and Education Group (2006) Repairing Scottish slate roofs. Historic Scotland, Edinburgh, UK

The Minnesota Lath & Plaster Bureau (2001) EIFS design 101. The Minnesota Lath & Plaster Bureau, St. Paul, MN USA

Thomas RG (1993) EIFS troubleshooting. Part I. Constr Dimens 25–26:33

Van Balen K (2015) Preventive conservation of historic buildings. Restor Build Monum 21:99–104. https://doi.org/10.1515/rbm-2015-0008

Verhoef LGW (ed) (1988) Soiling and cleaning of building façades. Report of Technical Committee 62 SCF RILEM. Taylor & Francis, Oxon, UK

Walter A, de Brito J, Lopes JG (2005) Current flat roof bituminous membranes waterproofing systems—inspection, diagnosis and pathology classification. Constr Build Mater 19:233–242. https://doi.org/10.1016/j.conbuildmat.2004.05.008

Weaver ME (1995) Removing graffiti from historic masonry. U.S. Department of the Interior, National Park Service Cultural Resources, Preservation Assistance, Washington DC, USA

Wilson F (1984) Building materials evaluation handbook. Van Nostrand Reinhold Company Inc., New York, USA

Ximenes S, de Brito J, Gaspar PL, Silva A (2015) Modelling the degradation and service life of ETICS in external walls. Mater Struct 48:2235–2249. https://doi.org/10.1617/s11527-014-0305-8

Icons Credits Licensed as Creative Commons CCBY

Drop by José Campos from the Noun Project

Paintbrush by ronin design from the Noun Project

Screwdriver by James Viola from the Noun Project

Thermometer by Dara Ullrich from the Noun Project

Download references

Author information

Authors and affiliations.

CERIS, Instituto Superior Técnico, University of Lisbon, Lisbon, Portugal

Jorge de Brito

Clara Pereira

José D. Silvestre

Inês Flores-Colen

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Jorge de Brito .

Rights and permissions

Reprints and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

de Brito, J., Pereira, C., Silvestre, J., Flores-Colen, I. (2020). Repair Techniques. In: Expert Knowledge-based Inspection Systems. Springer, Cham. https://doi.org/10.1007/978-3-030-42446-6_5

Download citation

DOI : https://doi.org/10.1007/978-3-030-42446-6_5

Published : 20 May 2020

Publisher Name : Springer, Cham

Print ISBN : 978-3-030-42445-9

Online ISBN : 978-3-030-42446-6

eBook Packages : Engineering Engineering (R0)

Share this chapter

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Publish with us

Policies and ethics

- Find a journal

- Track your research

An official website of the United States government

Official websites use .gov A .gov website belongs to an official government organization in the United States.

Secure .gov websites use HTTPS A lock ( Lock Locked padlock icon ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

- Publications

- Account settings

- Advanced Search

- Journal List

Intelligent systems for additive manufacturing-based repair in remanufacturing: a systematic review of its potential

Siti syahara mad yusoh, dzuraidah abd wahab, hiyam adil habeeb, abdul hadi azman.

- Author information

- Article notes

- Copyright and License information

Corresponding author.

Received 2021 Jul 19; Accepted 2021 Nov 18; Collection date 2021.

This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, reproduction and adaptation in any medium and for any purpose provided that it is properly attributed. For attribution, the original author(s), title, publication source (PeerJ Computer Science) and either DOI or URL of the article must be cited.

The conventional component repair in remanufacturing involves human decision making that is influenced by several factors such as conditions of incoming cores, modes of failure, severity of damage, features and geometric complexities of cores and types of reparation required. Repair can be enhanced through automation using additive manufacturing (AM) technology. Advancements in AM have led to the development of directed energy deposition and laser cladding technology for repair of damaged parts and components. The objective of this systematic literature review is to ascertain how intelligent systems can be integrated into AM-based repair, through artificial intelligence (AI) approaches capable of supporting the nature and process of decision making during repair. The integration of intelligent systems in AM repair is expected to enhance resource utilization and repair efficiency during remanufacturing. Based on a systematic literature review of articles published during 2005–2021, the study analyses the activities of conventional repair in remanufacturing, trends in the applications of AM for repair using the current state-of-the-art technology and how AI has been deployed to facilitate repair. The study concludes with suggestions on research areas and opportunities that will further enhance the automation of component repair during remanufacturing using intelligent AM systems.

Keywords: Additive manufacturing, Artificial intelligence, Repair and restoration, Conventional methods, Intelligent systems

Introduction

Remanufacturing as a strategy for product life cycle extension.

The circular economy (CE) offers an alternative perspective for recovery of durable technical systems and returning them to productivity as part of a sustainable future. It advocates designing out waste and pollution, retaining products and materials in use, and regenerating natural systems ( Kirchherr, Reike & Hekkert, 2017 ). Gan & Pujawan (2014) noted that rapid developments and innovations in science and technology have shortened the life cycle of products. This phenomenon is not in line with the principles of CE that promote sustainability through product life cycle extension. Environmental sustainability will be adversely affected by the overconsumption of natural resources and energy, causing a rapid increase in landfill waste. The principles are set to replace the ‘take–make–dispose’ concept of a linear economy, which relies heavily on resources and energy. The emphasis on regeneration and restoration of durable products to extend their useful life has become a subject of interest in product development, as it describes the recovery and restoration of products through strategies such as reuse, repair, remanufacturing or recycling ( Macarthur, 2015 ).

Hollander & Bakker (2012) outlined five modes for product life cycle extension: repair, recycle, maintenance, upgrade and remanufacturing. Based on a study on waste management for sustainability, Fedotkina, Gorbashko & Vatolkina (2019) reiterated the importance of reuse, remanufacturing and recycling as enablers of CE. Awareness of the principles of CE will help create ‘closing the loop’ in product life through repair and restoration ( Delos Rios & Charnley, 2017 ). Researchers that have compared remanufacturing with other end-of-life (EoL) recovery strategies such as recycling, suggested that remanufacturing is less energy intensive and more profitable ( Taleizadeh, Alizadeh-Basban & Akhavan, 2019 ; Tam, Soulliere & Sawyer-Beaulieu, 2019 ; Kalverkamp & Raabe, 2018 ; Wakiru et al., 2018 ).

To date, remanufacturing is the most value-added, resource-efficient strategy for EoL product recovery compared with recycling or reuse, as it enables products to be given a new life ( Hatcher, Ijomah & Windmill, 2013 ). Remanufacturing has been defined as the process of returning a used product to a ‘like new’ condition in terms of its original specifications and given a matching warranty ( Ijomah, 2010 ). Remanufacturing involves a series of activities, namely, disassembly, cleaning, inspection, repair, reassembly and testing on an EoL product before it can be reused in a new life cycle ( Matsumoto et al., 2016 ). Recent studies indicated that remanufacturing is a good alternative towards enabling CE; this will in turn, sustain the economy, the society and the environment ( Andrews, 2015 ; Parker et al., 2015 ). Based on the study by Van Loon & Van Wassenhove (2017) on manufacturing and remanufacturing of a chassis for automotive industry, the CO2 emission for a new chassis is 11.23 kg per item, whereas it is only 7.5 kg for remanufacturing. An earlier study by Biswas & Rosano (2011) showed that the emission of greenhouse gas for the production of a new compressor is approximately 1,590 kg CO2, whereas the emission for compressor remanufacturing is approximately 110–168 kg CO2. The ratio of energy benefits between remanufacturing and manufacturing is in the range of 2%–25% for engine diesel remanufacturing. An eco-efficiency analysis of remanufacturing and manufacturing of a cylinder block has shown that a remanufactured cylinder block shows better performance, which is 62% compared with a newly manufactured component in addition to reduction in price, use of material and air emissions ( Afrinaldi et al., 2017 ).

Remanufacturing maintains a product’s original functions and applications, with slight differences in its form, configuration or construction to support functions equivalent to those of the virgin product ( Soh, Ong & Nee, 2014 ). Through remanufacturing, the value of a used product can be retained ( Aziz et al., 2016 ). Extending a product’s life cycle not only reduces the product’s effect on the environment but also increases its economic value ( Hollander & Bakker, 2012 ). According to Amelia et al. (2009) , resources that have undergone the recovery phase enter a new life cycle, thus reducing or eliminating the usage of virgin materials. This finding was also explored in prior studies by Gray & Charter (2006) , who stated that remanufacturing reduces energy and natural material consumption and costs. Kara, Pornprasitpol & Kaebernick (2006) noted that remanufacturing reduces the environmental influence of a product and improves eco-efficiency. For a successful remanufacturing, a product should possess a stable technology for more than one cycle ahead ( Amelia et al., 2009 ). Yusop, Wahab & Saibani (2015) described remanufacturing as one of the factors in achieving environmental sustainability and has a direct positive effect on economic growth in terms of cost saving and profit obligations. Aprilia et al. (2018) noted that high-value components such as turbine blades, impeller and shafts are preferred to be remanufactured rather than replaced with new ones.

This study focuses on the repair and restoration process of remanufacturing. Despite the significance of remanufacturing as one of the recovery strategies in CE, remanufacturing is labour intensive because it is highly dependent on skilled and experienced workers and the use of conventional tools for component repair and restoration. Therefore, automating the process is crucial such that productivity and process consistency can be controlled and improved. Aprilia et al. (2018) noted that manual remanufacturing is prone to human error, inconsistency in output quality and labour intensive with a high cost. Automating the activity is crucial to enhance productivity and process consistency.

Literatures on the use of advanced additive manufacturing (AM) technology such as direct energy deposition and cold spray in component repair have grown in recent years. However, these technologies have yet to be integrated with the capability to replicate human judgement and decision-making performed during conventional remanufacturing repair and restoration in order to provide intelligence in machine learning (ML).

The conventional repair and restoration in remanufacturing demands skilled and experienced workers who can make decisions on whether incoming products are worthy of remanufacturing. For example, during core inspections, workers have to assess the conditions of the cores that include types of damage, severity of damage, geometric complexity and availability of the right tools. Each incoming core has different levels of conditions and geometrical complexity, causing vagueness and uncertainties in decision making. Human decision making for repair and restoration is influenced by factors such as product features and geometry, mode and severity of damage and failure as well as process and system capabilities. An intelligent system based on artificial intelligence (AI) can capture these information and knowledge on design and process that facilitates knowledge sharing and ML for automation. Models for decision making, prediction and optimisation can be developed through AI techniques, resulting in a more consistent, efficient decision making. Representing knowledge and heuristics on repair and restoration through hybridised techniques of fuzzy logic, case-based reasoning (CBR), neural networks will enable various improvements in quality and reliability of products and process efficiency.

This study provides a systematic review on the potential of AM in automating remanufacturing repair through an integration with AI-based intelligent systems. The first part of the findings reports on remanufacturing as one the strategies of product life cycle extension in CE, followed by an overview of conventional methods and automated process for repairing components. For the purpose of this review, the automated process is focused on the application of AM technology. The review also provides a coverage of literature that address the applications of AI in component repair. The review concludes with research gaps in the field of study and suggestions for further research and exploration for the integration of AI-based intelligent systems in AM for component repair.

Remanufacturing repair and restoration: practices and challenges

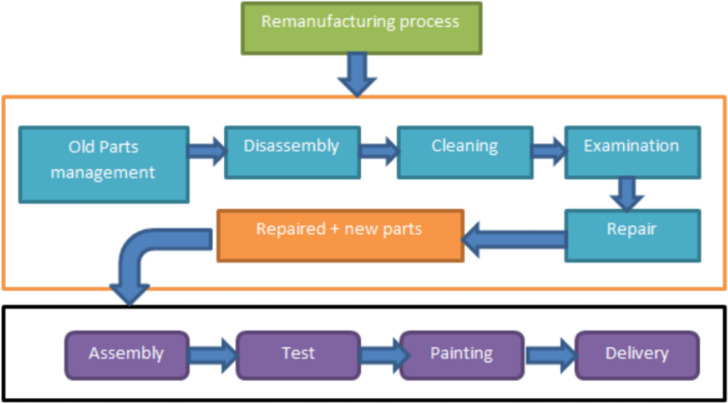

Remanufacturing involves several processes: sorting, disassembly, inspection, cleaning, repair and restoration, reassembly and testing. These processes are commonly performed using conventional methods by highly skilled, experienced workers ( Hatcher, Ijomah & Windmill, 2013 ; Yilmaz, Gindy & Gao, 2009 ; Wahab et al., 2018 ). Figure 1 depicts the general processes involved in remanufacturing.

Figure 1. Remanufacturing process ( Jiang, 2016 ).

The general processes involved in remanufacturing.

Despite the importance of remanufacturing in terms of socio–economic gains, companies are facing challenges in implementing efficient remanufacturing because activities such as disassembly, cleaning and inspection of damaged components and repair rely on conventional methods.

Generally, repair and restoration are aimed at returning EoL components to their original form before entering the subsequent life cycle. Kin, Ong & Nee (2014) noted that manual restoration consists of a sequence of processes to ensure that cores are free from damages. Component repair may involve the removal of surface and shape defects using conventional processes such as turning, milling, drilling and grinding, after which a material or a surface is replaced using other processes such as welding and powder coating. Next, material properties are restored through conditioning, such as heat treatment or case hardening involving carburising. Finally, parts undergo surface finishing to achieve dimensional tolerances using processes such as grinding, hard turning and burnishing ( Kin, Ong & Nee, 2014 ). According to Andrew-Munot & Ibrahim (2014) , manual repair and restoration of damaged parts with complex designs require multiple repair processes, such as cutting, welding and trimming. Priyono, Ijomah & Bititci (2015) stated that repair and restoration may involve treatment to the surface, such as blasting and building up worn-out parts by means of metal spraying and welding.

Metal deposition on damaged surfaces is normally carried out using arc welding, gas tungsten welding and other methods ( Wilson et al., 2014 ). According to Widener, Ozdemir & Carter (2018) and Subramoniam, Huisingh & Chinnam (2009) , these workers have to decide whether a product should be repaired or replaced during remanufacturing. Making the right decisions is crucial when selecting the appropriate repair and restoration because they depend on the type of damage of each component ( Lahrour & Brissaud, 2018 ), whether products should be remanufactured ( Paterson, Ijomah & Windmill, 2017 ), selection of toolings and techniques in the disassembly ( Soh, Ong & Nee, 2014 ) and analysing variables such as successful remanufacturing rate, number of product life cycles and environmental performance ( Yang et al., 2015 ).

Casper & Sundin (2018) noted the difficulties in repairing cores with a complex design because it requires highly skilled, experienced workers. Issues such as lack of consideration on design for remanufacturing during the early design phase of products have led to remanufacturing inefficiency ( Kurilova-Palisaitiene & Sundin, 2014 ). Matsumoto et al. (2016) pointed out several challenges in remanufacturing automotive parts and photocopiers such as product and process design to facilitate remanufacturing, engineering and optimisation. Process design such as the method for joining parts is crucial in achieving efficient remanufacturing. Yang et al. (2015) highlighted problems in remanufacturing, such as high degree of damage to incoming EoL components, lack of technology and equipment, and substantial involvement of manual labour. The processes of disassembly, cleaning and inspection of core parts also face difficulties due to the presence of highly contaminated oil, oxide and operational liquid ( Yang et al., 2015 ).

Shahbazi, Johansen & Sundin (2021) have reported on several advantages of using automation in remanufacturing. According to the authors, separating the material of the component into different sections is easier using an automated system that increases efficiency and productivity, and reduces lead time as well as the cost involved.

Survey methodology

This review is part of a research funded by the Ministry of Higher Education, Malaysia (JPT(BKPI)1000/016/018/25(72)) aimed at integrating product design and process efficiency during AM repair and restoration in remanufacturing through the applications of AI based systems. The review methodology is an adaptation of the methods used by Linares-Espinós et al. (2018) and Campbell et al. (2020) . This work starts by identifying research questions that will answer the primary objectives and address the scope of this review. Linares-Espinós et al. (2018) stated that a review should be carried out when developing and planning to reduce biased, irrelevant and low-quality studies. The findings from the review are analysed and synthesised accordingly. An exploratory search on the related topic is carried out using relevant publications to fulfil the requirements of the scope of the review. Once the research questions are developed, the related hypotheses are formulated as follows: ‘If AM technology is applied to the current remanufacturing activities, then difficulties in the manual process can be solved’, and ‘If an intelligent system is integrated with AM technology, the repair process can be performed with minimal human intervention’. The formulated hypotheses have led to a more focused, systematic search and analysis of the research topic.

Challenges and difficulties in conventional repair during remanufacturing are highlighted in this paper. The applications of AM technology as the way forward in component repair during remanufacturing are thoroughly searched and discussed in the context of a sustainable technology in supporting CE. In the last part, the applications of intelligent systems based on AI in component repair are reviewed and discussed as the way forward in supporting the remanufacturing industry. Intelligent systems in this context include the applications of AI techniques in recognising damaged areas on parts, predicting part distortion, detecting part failure and decision making during repair.

Okoli & Schabram (2010) noted that several steps should be followed when conducting a systematic literature review. The first step is to select research questions, bibliographic or article databases, websites or other sources, and select the right search terms. This step is followed by applying practical screening criteria for the relevant literature and the methodological screening criteria. The final step is to analyse and synthesise the findings from the literature review. Table 1 shows the research questions from which the search terms were identified and used to obtain the related publications on ‘remanufacturing’, which was firstly focused on the manual process, followed by automation using AM to search information on the current technology that is generally in use. The term ‘repair and restoration using additive manufacturing’ was then used to narrow the scope of the search. This study emphasises the application of AI technology within AM repair in remanufacturing systems and its implementation. Therefore, the terms ‘artificial intelligence’ and ‘machine learning’ were used to search the related information. Remanufacturing is highly related to sustainability and CE together with ‘life cycle’, and the following search terms were used: ‘sustainability’, ‘circular economy’, ‘life cycle’, ‘strategy for life cycle extension’, ‘intelligent manufacturing’, ‘intelligent systems in remanufacturing’, ‘intelligent systems in reparation’, ‘AI method for reparation’, ‘AI application in reparation’, ‘additive manufacturing in circular economy’ and ‘artificial intelligence in circular economy’.

Table 1. The research questions from which the search terms were identified and used to obtain the related publications.

Research questions.

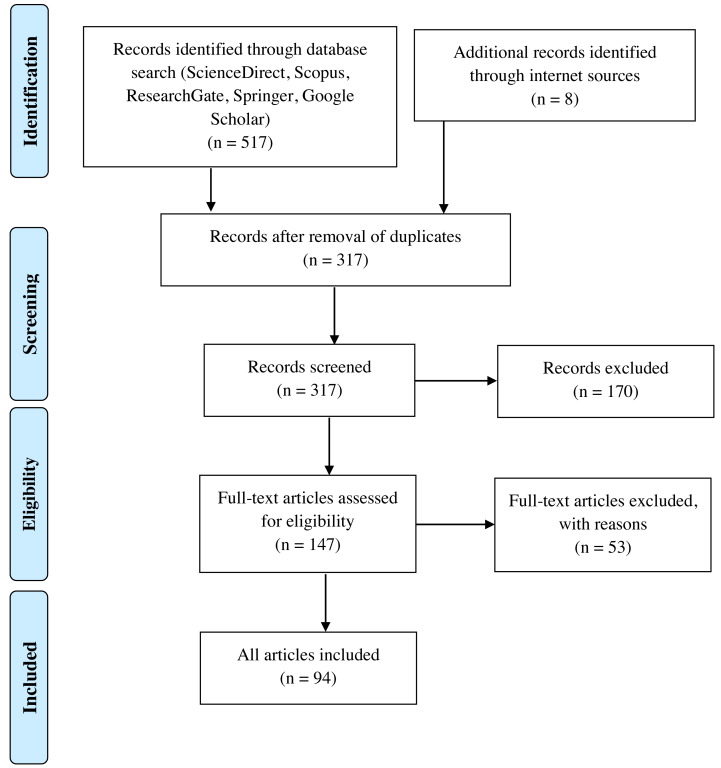

To obtain the full text of the publications from those search terms, databases of several publishers, such as Elsevier ( http://www.sciencedirect.com and http://www.scopus.com ), Research Gate ( http://www.researchgate.net ) and Springer ( http://www.springer.com ) were used. Google Scholar was also used to search for journal publications and conference proceedings. For the purpose of the systematic review, articles were selected from 2005 to 2021 to ensure that the review is up to date, and research trends can be determined throughout the specified timeline. Once the related publications were obtained based on the search terms, a two-level screening process was carried out starting with the first level screening which focused on the title and abstract. The second level screening was carried out based on a full-text review. After an initial screening of 517 citations and removal of duplicates based on title and abstract, 317 citations were obtained. The items were further screened for eligibility based on a full-text review resulting in 147 full-text articles; the 170 other articles were excluded because they were out of relatable context. Articles excluded will be counted to complete the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) flow diagram as shown in Fig. 2 . The articles were screened further to meet the inclusion criteria which is AM and AI technology applied in any country, any AM and AI method applied in enhancing the remanufacturing activity, automated repair and restoration using enabling technologies and intelligent repair and restoration through AI and ML. This will include the studies of experiences, perceptions, opinions on potential use and related case studies, resulting in 94 items.

Figure 2. Process flow for a systematic review of related articles.

Illustration of the process flow for the systematic review of related articles.

Only articles published in English were used as reference to avoid language bias ( Suhariyanto, Wahab & Rahman, 2017 ). The review was focused more on case studies in industries such as aerospace, automotive, mould and die, and archaeology, in which the application of AM has been reported. In addition, AM technologies other than metal AM were excluded from this review. Figure 2 illustrates the process flow for the systematic review of related articles.

Repair and restoration in remanufacturing

Component repair during remanufacturing can be broadly classified into conventional and automated processes. The process begins after cores are disassembled, sorted and inspected. Kin, Ong & Nee (2014) noted that returned products might exhibit defects ranging from minor scratches to considerable damage; thus, inspection and sorting are required to filter valuable cores. Common types of defects are cracks, scratches, nicks and burrs as well as burnt or corroded regions. The following sections discuss remanufacturing repair and restoration that are classified as conventional methods and automated methods using AM technology.

Conventional repair and restoration

Repair and restoration in remanufacturing is aimed at returning parts or components to their original forms or dimensions. Researchers such as Kin, Ong & Nee (2014) have discussed methods for the removal of surface and shape defects prior to material addition using processes such as turning, milling, drilling and grinding. Welding, one of the most common conventional processes, was reported by Kim et al. (2012) as the method for repairing cracks on the surface of an engine block head. Bennett et al. (2019) noted that welding has also been used extensively in the repair of aircraft components, such as gas turbine blades. The setbacks of welding have also been reported by researchers in the field of study. Amongst the setbacks are exposure of the parent metal to high temperatures causing the formation of heat-affected zone that alters the properties of materials ( Ramkumar et al., 2014 ) and the need to remove material before the damaged area can be restored ( Balakrishnan & Seidlitz, 2018 ; Walachowicz et al., 2017 ). Kurilova-Palisaitiene, Sundin & Poksinska (2018) noted that compared with manufacturing, remanufacturing involves a higher proportion of manual work that may lead to a prolonged lead time, rendering inefficiency in remanufacturing. This labour-intensive process that directly imparts factors related to human limitations affect the flow of the repair process; thus, proper restoration measures are needed ( Balakrishnan & Seidlitz, 2018 ).

Automating repair using additive manufacturing

Today, advancement in AM technology has expanded its role from part manufacturing to part repair and restoration. Sauerwein et al. (2020) stated that AM supports circular design strategies by creating opportunities in extending a product lifespan, for example, enabling the reparation and upgrading of products even though the product is not designed for ease of repair or upgrade. Moreover, broken parts of products can be reproduced by digital production to support reparation. According to Huang et al. (2014) , AM allows the creation of complex geometries that will lead to reduced energy consumption and material usage, and increased product functionality and simplified assembly lines.

Metal AM has two types of processes: direct and indirect. The direct process is laser beam melting, also known as selective laser melting (SLM), laser cladding and laser-engineered net shaping (LENS) ( Boschetto et al., 2019 ). Directed metal deposition (DMD), also known as directed energy deposition (DED), consists of several methods, such as LENS, laser cladding and cold spray ( Herzog et al., 2016 ). The indirect process refers to 3D printing, which includes selective laser sintering and stereolitography ( Boschetto et al., 2019 ).

Yeo, Pepin & Yang (2016) noted that to reduce the challenges and enhance remanufacturing, automated systems should be deployed for critical repair and restoration processes. Several authors have highlighted the benefits of AM in terms of efficiency, time saving and its ability to work with intricate designs compared with conventional techniques ( Liu et al., 2017 ; Ko, Moon & Hwang, 2015 ). AM, as one of the enabling technologies of Industrial Revolution (IR) 4.0, could provide potential benefits in terms of sustainability in remanufacturing because it can extend a product’s life cycle ( Den Boer, Lambrechts & Krikke, 2020 ; Ford & Despeisse, 2016 ).

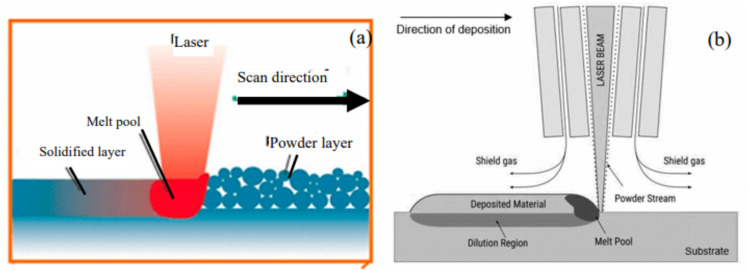

To date, AM technologies such as powder bed fusion (PBF) and DED have paved the way for AM applications in repair and restoration. The technology has also been recognised as environmentally sustainable due to its ability to minimise energy and material consumption. Figure 3 shows a schematic diagram of PBF and DED.

Figure 3. Schematic diagram of (A) PBF and (B) powder-based directed deposition ( Saboori et al., 2017 ).

Schematic diagram of PBF and DED.

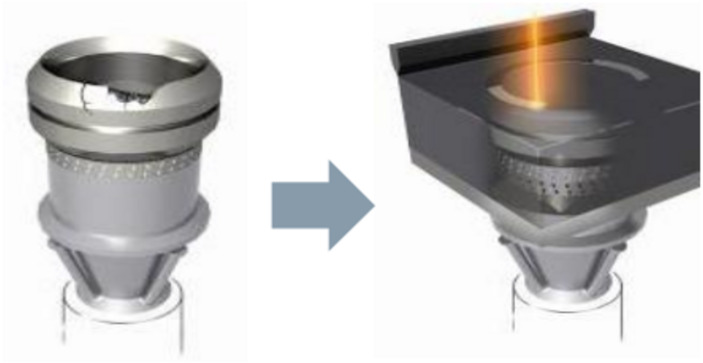

PBF has been widely used in manufacturing replacement components on demand as well as reparation of damaged components. Generally, PBF is a process of layer-by-layer building of material by channelling laser beams into a thin layer of powder deposited on a fusion bed ( Okaro et al., 2019 ). However, its limitation is that new materials need to be in the form of a planar surface within the tolerance of the powder layers ( Matsumoto et al., 2016 ). An example of a component that can be repaired using PBF is the burner tip of a gas turbine using SLM technology, as shown in Fig. 4 ( Navrotsky, 2019 ). The tip of the burner is machined to remove the damaged area before it is placed into the powder bed.

Figure 4. Repair of a gas turbine burner tip.

Example of a component that can be repaired using PBF is the burner tip of a gas turbine using SLM technology.

Matsumoto et al. (2016) reported on the use of DED for component repair in remanufacturing. The process uses a focused thermal energy beam to melt and fuse materials. Material in powder form is added by injecting a flow of powder and inert gas into the fusing zone through a nozzle or the mechanical feeding of wire from a spool. Depositing the material onto the damaged surface is easier compared with the PBF technology. It can also add more wear-resistant material to the outer surface than the original material, thus improving the functionality of the remanufactured part. The American Society for Testing and Materials classified AM technology into seven categories, namely, material extrusion, material jetting, binder jetting, DED, PBF, sheet lamination and VAT polymerisation ( Huang et al., 2016 ). This literature review focuses on AM technologies that have been applied in component repair and restoration, namely, PBF and DED. Leino, Pekkarinen & Soukka (2016) noted that DED is expected to be one of the enabling technologies in CE that can support repair, refurbishing and remanufacturing activities. A comparison between DED and PBF in terms of technology and repair principles is presented in Table 2 .

Table 2. Comparison between DED and PBF in terms of technology and repair principles.

Comparison between ded and pbf technology.

Based on extensive literature, a number of articles that addressed the application of AM in repair and restoration were identified. Table 3 provides a summary of selected articles that discussed the applications of AM for various types of reparation.

Table 3. Summary of articles on the applications of AM in repair and restoration.

Summary of selected articles that discussed the applications of AM for various types of reparation.

Summary of articles on the applications of AM in repair and restoration

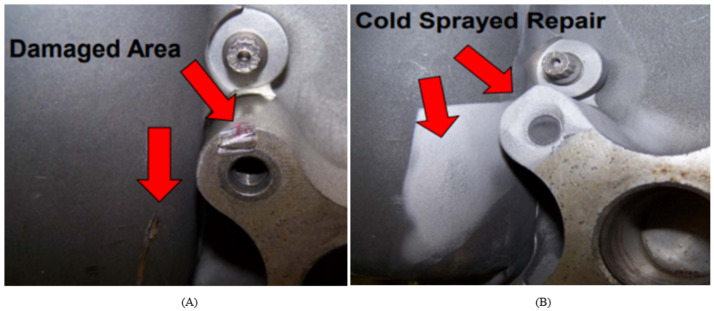

Yin et al. (2018) investigated the use of cold spray technology for repair and restoration of damaged components. Originally developed as a coating technology in the 1980s, cold spray technology is a solid-state material deposition using high-temperature compressed gas, typically nitrogen, air or helium, as a propulsive gas to accelerate a powder feedstock to a high velocity and induce deposition when the powder impacts onto a substrate. Cold spray has a high potential for repairing damaged components due its ability to avoid thermal damage to the material. The technology has been used in various fields for repairing damaged and corroded materials, as shown in Fig. 5 . Examples of components that have been repaired using cold spray are corroded transmission gearboxes in aircrafts, corroded air pump housings in the automotive industry, valve actuators in the marine industry and damaged moulds ( Widener et al., 2016 ; Kok et al., 2017 ; Lyalyakin, Kostukov & Denisov, 2016 ; Yin et al., 2018 ; Lee et al., 2007 ; Okaro et al., 2019 ).

Figure 5. Application of cold spray technology (A) Before repair (B) After repair.

The cold spray technology that has been used for repairing damaged and corroded materials.

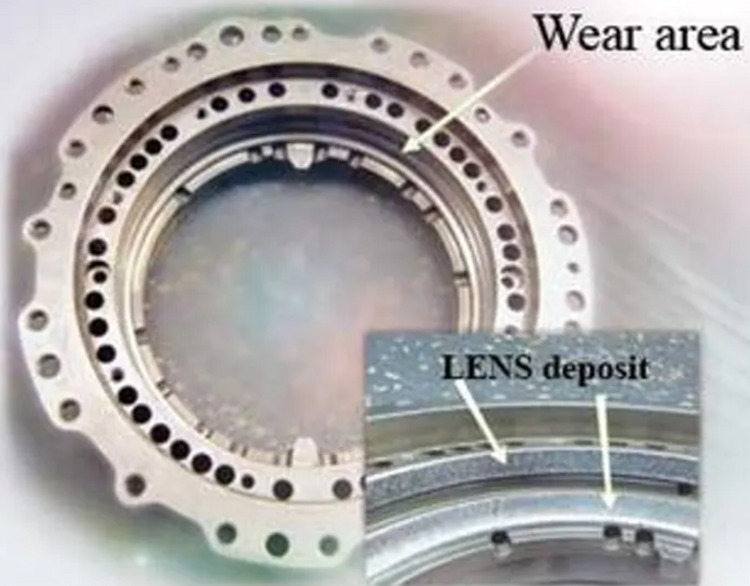

LENS is characterised as a disruptive additive process that can be employed in a variety of processes for repair and free-form fabrication. This technology can be used for repairing worn-out components, building near net-shaped free forms directly from CAD files and cladding materials. LENS works by melting the surface of the target using a focused laser beam to generate a small molten pool of the base material. Examples of damaged components that have been repaired using LENS are bearing housings, drive shafts, gas turbines, compressors and drive couplers ( Mudge & Wald, 2007 ). Figures. 6 and 7 show a bearing housing and a compressor seal repaired using LENS.

Figure 6. Bearing housing repair using LENS technology.

Examples of damaged components that have been repaired using LENS.

Figure 7. Compressor seal repair using LENS technology.

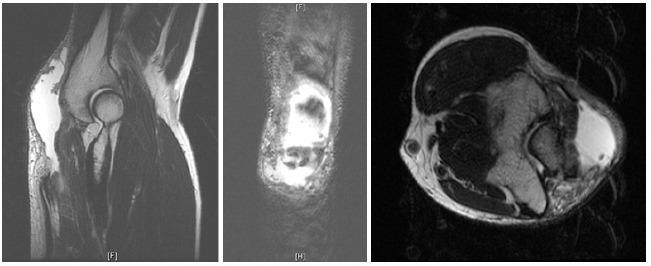

Kamrani (2014) studied component repair during remanufacturing using direct laser deposition technology, known as LENS, and laser cladding. Typical damages of remanufacturable components include abrasion, seizure, fretting, erosion, cavitation and fracture spalling. According to Kamrani (2014) , the most severe type of damage is abrasive defect caused by small particles penetrating and indenting the surface of a material. AM remanufacturing is preferred to traditional machining, as less time is required to work on complex models or geometries, and no waste material is created. LENS and laser cladding can be applied in remanufacturing for various industries such as automotive, aerospace, medical, and oil and gas ( Kamrani, 2014 ; Linton, Klassen & Jayaraman, 2007 ). Kamrani (2014) studied the potential of direct laser deposition in component repair based on damage types; however, the processes involved in repairing these components were not addressed. Linton, Klassen & Jayaraman (2007) discussed the role of AM in product life extension that is now the way forward in IR 4.0.

Liu et al. (2016) discussed the use of laser cladding during remanufacturing of damaged cylinder heads made of cast iron. The damage occurs as a crack between the valve seats of the air inlet and the exhaust port on top of the cylinder head. Liu et al. (2016) also made a comparison between the use of conventional welding and laser cladding for reparation, which resulted in laser cladding being the more favourable option. Welding affects the substrate, leading to a higher residual stress that may initiate secondary cracks. By contrast, laser cladding has a higher forming accuracy, a lower substrate thermal effect zone and better mechanical properties, apart from retaining the same quality and performance as the original condition. Laser cladding has also been widely used for repairing camshafts and turbine blades ( Liu et al., 2016 ). The study focused on the environmental effect of laser cladding but provided no detailed explanation on the repair.

Buican, Oancea & Manolescu (2014) studied the applications of SLM technology in repairing the broken teeth of a sewing machine gear during remanufacturing. SLM enables direct melting of metal powders such as titanium, steel, chrome, cobalt and aluminium alloys, which are built using the layer-on-layer approach. In this method, the laser beam acts as the energy supplier to melt a layer of deposited metal powder and fuse it into the previously melted layer. With the use of AM, processes such as scanning, repairing and remanufacturing can be implemented within a day with the aid of technical information on the specifications of the damaged parts. The authors provided a detailed explanation on the reparation of gear teeth using SLM.

Yilmaz, Gindy & Gao (2009) studied and improved the remanufacturing of aero engine components using AM. Aero engine components such as blades, vanes, combustors and shafts are easily damaged due to exposure to harsh environments and long operating hours. Typical forms of damage to these components are distortions, wears, impacts dents and cracks. Damaged blades are restored to their original shape and efficiency because they are critical to the operations and performance of the system. Yilmaz, Gindy & Gao (2009) proposed reparation using laser cladding, followed by removal of the excess material using a conventional machine.

Researchers such as Al Handawi et al. (2020) highlighted the need to address limitations in AM repair from the perspective of environment, economics and social. Morrow et al. (2007) compared the economic and environmental effects of AM repair and conventional machining (CNC milling) in the tooling industry. Whilst both processes showed a trade-off between economic and environmental effects, AM repair fared better in terms of energy reduction and material inventory because AM requires only a specified amount of the material. Aziz et al. (2021) discussed the pros and cons of the welding method (conventional) and AM. Despite the limitations in both methods, the authors highlighted the contributions of AM to environmental sustainability such as environmental footprints from component manufacturing process can be reduced ( Huang et al., 2016 ), the capability to extend the product’s life is enhanced ( Den Boer, Lambrechts & Krikke, 2020 ; Ford & Despeisse, 2016 ) and the process is environmentally friendly ( Aziz et al., 2021 ).

Liu et al. (2016) focused on the environmental effects from the remanufacturing of cast iron cylinder head block through laser cladding using life cycle assessment. In the study, the energy consumption for manufacturing and remanufacturing was collected. It was also reported that remanufacturing can reduce environmental impact by 63.8% on average. The steps involved in remanufacturing the cylinder head was discussed briefly and to conduct a scenario analysis, the crack on a worn cylinder head was assumed repaired. Based on the study, the energy consumption for manufacturing a single part of cylinder head is higher, 112.75 KWh, compared with the energy consumption for remanufacturing that is approximately 91.75 KWh. According to Faludi et al. (2016) , 85% of energy is used for CNC machining including excess material removal after processing. However, AM can save energy of up to 45%–61% based on type of process and machine used, which is 45% for Thermojet, 43% for EOS and 61% for FDM.

Despite the growing interest in automating repair using AM, reports on the requirements from product, process and system perspectives are limited. To date, the practical applications of AM for repair are still limited, especially in developing countries due to the high acquisition and maintenance cost of AM technology such as DED and the competencies needed to handle such machines.

Application of intelligent systems in manufacturing

Recent literatures for example by Rezaei, Houshmand & Fatahi Valilai (2021) highlighted the application of AM, AI and cloud manufacturing as pillars for digitised IR. The authors used convolutional neural network to interpret geometrical shapes of 3D objects from 2D pictures for categorisation into simpler shapes and analysed their production automatically using AM. The proposed method can reduce cost and time in addition to creating a fully automated platform in the manufacturing system.

Sadeghi Aghili et al. (2021) proposed the application of cloud manufacturing and service-oriented process to enable the transition of conventional manufacturing business model into a more efficient and productive one by using algorithm and solve the scheduling problems of logistics and manufacturing. Industrial AI for Industry 4.0 in manufacturing was proposed by Lee et al. (2018) as a solution for real-time monitoring and performance prediction of machine tool spindle in CNC machine. The proposed AI application is capable of minimising maintenance cost and optimising product quality simultaneously. For the purpose of this paper, the application of AI technology is focused on repair and restoration during remanufacturing.

Application of intelligent systems in AM repair and restoration

The current production systems are more complex, dynamic and chaotic in behaviour, but fulfilling customer demand through high-quality production based on ML in intelligent production systems is necessary. According to Wuest et al. (2016) , AI is one of the most interesting developments of ML. Kashyap (2017) highlighted the widespread applications of AI in demand forecasting, error detection, equipment failure prediction and pattern recognition. AI is also important for predicting machinery failures and maintenance, optimising energy consumption, predicting part failure and effective decision making ( Kashyap, 2017 ).

AI provides various algorithms, theories and methods, and offers great potential to transform the current manufacturing technique under the situation of ever increasing data repository. Through ML in manufacturing, useful information can be derived from existing data sets, thus providing a basis for approximations or predictions that allow machines to operate with future behaviours such as decision making and automatic system improvement. It is also beneficial for detecting certain patterns or exploring regularities in a dynamic manufacturing environment ( Wuest et al., 2016 ).

ML can be defined as the process of computers being taught the ability to extract important information from examples automatically or the capability of machines to build on the strength of big data to optimise the process, find new solutions and gain new insights. It can make predictions based on a large amount of data and process the ability to recognise patterns and learn from experience ( Ma & Okudan, 2015 ). Ansari, Erol & Sihn (2018) noted that ML can improve quality through systems training using large datasets, whereas humans can be influenced by personal, societal or institutional interests during decision making. Moreover, humans become fatigued and dissatisfied with their job, whereas machines can operate for countless hours. Table 4 presents a summary of selected articles on the application of AI techniques in damage and failure detection.

Table 4. Applications of AI-based techniques in repair and restoration.

Summary of the work reported in the related articles

According to Liu et al. (2018) the main goal of AI is for human and machine to be integrated and coexist harmoniously to ensure efficiency in carrying out tasks through the implementation of intelligent machine. As for Industry 4.0, which is highly related to smart factories, it will be controlled physically by machine intelligence for autonomous, flexible manufacturing purposes embedded in the planning, production and management processes for real-time decisions ( Terziyan, Gryshko & Golovianko, 2018 ). The implementation of big data technology will create a revolution of traditional technology that will improve product quality, increase production efficiency and reduce energy consumption ( Chen et al., 2018 ).

French, Benakis & Marin-Reyes (2018) discussed the implementation of robotic AM in aerospace maintenance, repair and overhaul of components, such as vanes, turbine blades and compressor blades, aimed at retaining the functionality and long-term reliability of the components. The authors proposed that AM, which is a series of welding trials consisting of monitoring welding, predicting quality and detecting the occurrence of errors and damage, be automated. In addition, a robotic welding system, which will soon be able to reshape the aerospace remanufacturing industry, can be implemented based on Industry 4.0 principles. According to the concepts of Industry 4.0, robotic systems that can adapt to changes in the repair process can provide better quality control and a higher success rate. A smart factory can also increase production speed and have an excellent quality assurance. The study detailed repair and overhaul activity in the aerospace industry. The authors also noted that developing this high technology for future automotive component repair and restoration is possible. The approach will reduce time, waste, production costs and dependency on a highly skilled workforce for selected repair processes.

To date, AI has been widely deployed in various applications of component repair. Table 4 provides a summary of the work reported in the related articles.

Applications of AI-based techniques in repair and restoration

Kashyap (2017) highlighted the widespread applications of AI in error detection, equipment failure prediction and pattern recognition. Nasiri, Khosravani & Weinberg (2017) noted that artificial neural networks (ANNs) have been used to detect faults in the rotor system of helicopters and can predict crack growth for sheet material. Fang et al. (2020) reported on the use of deep learning in malware detection that achieves better results with a high effectiveness. Moreover, feature extraction for malware detection performs better with deep learning ( Fang et al., 2020 ).

The artificial bee colony (ABC) algorithm was applied by Kurilova-Palisaitiene, Sundin & Poksinska (2018) in the detection of faults in the gearboxes of mechanical equipment. The conventional methods used in gearbox fault detection are time domain, frequency domain and time–frequency domain. The authors proposed an integrated system based on support vector machine and ABC, and their study showed that the proposed method took less time to collect vibration signals for the diagnosis of gearbox failure than the conventional method. AI techniques have also been used in the fault diagnosis of automatic bearing using a combination of particle swarm clustering and the Hidden Markov Model. The application proposed by Yuwono et al. (2016) involved a mathematical model for the proposed framework, and the experiment showed that the hybrid techniques distinguished the defects with a lower error rate.

CBR is an AI technology for problem solving that relies on learning and reasoning based on previous experience ( Yang et al., 2015 ). This technique has also been used for detecting mechanical failures in a component ( Yuwono et al., 2016 ). The approach can reduce dependency on extensive knowledge and information on failure analysis. According to Nasiri, Khosravani & Weinberg (2017) , the CBR technique has been used for the detection of leakage in gas and steam turbines, which helps in decision making, whilst reducing maintenance costs and increasing the efficiency of expert systems. Xiang et al. (2008) successfully applied GA in the detection of crack locations on shafts and the depths of the shafts. All these techniques can be integrated with ML for detecting component failure and its severity, such as corrosive surfaces, cracks, dents and scratches during repair and restoration in remanufacturing.

Francis & Bian (2019) proposed an intelligent system based on deep learning for laser-based additive manufacturing (LBAM). The aim of the system is to overcome challenges in geometric accuracy to predict distortion accurately. Based on the system, distortion that usually occurs during part fabrication was predicted on various geometries for end-use applications. The accuracy and efficiency of LBAM was improved after using this approach. The output of the study was also an enabler for Industry 4.0. According to the authors, the method cannot be directly applied on the boundary of complex parts. For complex parts, a combination of more than one method, such as combining the proposed method with ANN was proposed. Kurilova-Palisaitiene, Sundin & Poksinska (2018) stated that lack of automation in companies and the complex geometry of components are amongst the challenges that cause inefficiencies in remanufacturing.

French, Benakis & Marin-Reyes (2018) proposed a system that used a robotic arm system to automate the repair of an aerospace component, which is the tip of a blade that has complex geometries and different repair requirements. This tip repair relied heavily on highly skilled welding engineers who use GTAW-based AM in repairing. The proposed system is an intelligent 3D scanning that will ensure that the surface quality meets the requirements for repair to calculate in parallel the AM deposition path of the system. The working principle of the system is the transparency of information between suppliers, manufacturers and customers, which has a recording of its history since manufacturing. According to the authors, the system can provide detailed reports on each individual manufactured component. The online process monitoring, the concept of industrial informatics and the component regeneration process will then be transformed into cyber–physical systems to obtain an optimum weld quality.

Discussion and Future Research Directions

Through remanufacturing which is one of the EoL recovery strategies of CE, EoL components are repaired and reused in their new life cycle in an as-good-as-new condition. To enable efficient repair using AM, the design of components has to be planned to support such recovery strategies and methods from the perspectives of design features and geometrical complexity, material compatibility and process system capabilities. 3D printing techniques, or AM technology will make design options of products become countless because the technology allows the creation of complex geometries whilst reducing material usage and energy consumption ( Huang et al., 2014 ). Recent advancements in AM have further leveraged its potential in component repair and restoration. Through AM integration with AI technology in ML, human thinking and decision making can be replicated to enhance design and process efficiencies in repair and restoration, thus improving the circulatory of materials and products. CE is a potential solution in minimizing the exploitation of resources and maximizing the prevention of waste to make better use of resources ( Velenturf & Purnell, 2021 ).

According to Macarthur (2019) , technology such as AI can unlock CE opportunities by improving design to empower cycles of reuse, repair, refurbishing and recycling of technical materials. According to Akinode & Oloruntoba (2020) AI is a key driver of IR 4.0 that can bring dreams of CE vision to fruition. Ghoreishi & Happonen (2020) stated that AI enables the transfer of precise data and information on materials and product availability, condition and accessibility that will lead to ease of monitoring. This process will lead to remote maintenance as well as remanufacturing, reuse and repair opportunities.

As reported in the earlier section, AI has been deployed in various applications of repair and restoration from detection of errors, defects and failures in components and machines to the diagnosis and prediction of failures in parts and components. AI techniques deployed in the earlier work include genetic algorithms, artificial neural network, fuzzy logic, case-based reasoning, Bayesian network and their hybrid techniques. Most of the studies have focused on determining the accuracy and precision of the developed techniques. The knowledge and heuristics involved in the process of decision making were not discussed at length. Knowledge and heuristics are crucial aspects of human judgement and decision-making during the repair and restoration, more so in remanufacturing when products are expected to be returned to their original specifications.

During a conventional process of repair and restoration, workers have to assess the conditions of the cores that include types of damage, severity of damage, geometric complexity and availability of the right tools. Each incoming core has different levels of conditions and geometrical complexity, causing vagueness and uncertainties in decision making. AI techniques such as fuzzy logic, ANN, CBR and their hybrid methods can represent this human decision making. The output from such systems will be useful for component design optimisation to facilitate repair using AM. A fuzzy-based system for example, comprising rules on the conditions of the EoL components should be able to assist in deciding whether components can be repaired and returned to their original specification. The basic system will require appropriate sensors for component and failure detection to be integrated with such fuzzy-based systems. Optimisation methods such as genetic algorithm and other evolutionary optimisation methods can be further deployed for process and cost optimisation.

AI-based optimisation methods have grown exponentially over the last decade. The integration of AI techniques in repair and restoration using AM should be able to support optimisations in product design to facilitate repair using AM. Meanwhile, process optimisation is necessary to ensure repair effectiveness and cost efficiency through the use of predictive techniques such as neural network, hence remanufacturing worthiness and economic returns of the repaired component can be ascertained.

The following discussion as itemised below, provides insights from the literature review whilst highlighting remarkable issues and opportunities for further enhancement of automated repair and restoration using AM through the integration of AI systems.

Manual repair and restoration of components or parts in remanufacturing requires skilled and experienced workers to make effective decisions to ensure that remanufactured parts are returned to their original specification. Decisions are influenced by the conditions of the incoming cores such as mode of failures, severity and locations of damages, difficulty in reparation due to geometrical complexity and use of nonstandard components, and selection of the appropriate repair processes or tooling. Factors such as unavailability of skilled, experienced workers and human limitations such as inconsistency in the quality of output, are several of the reported challenges in remanufacturing. Automating the repair process with the support of intelligent systems should be the way forward, as it is crucial to ensure efficiency and consistency in the quality and the reliability of the remanufactured components. Through AI, product design data and information can be captured and shared within a smarter remanufacturing environment.

Advancements in AM technology have extended the conventional role of AM from part fabrication to part repair and restoration. DED and laser cladding technology have been widely reported as the most capable AM technology for conducting repair and restoration. Whilst the technology is relatively new and the cost is high, several papers have reported the advantages of AM in repair efficiency. The contribution of AM to environmental sustainability has also been highlighted by several researchers.

Despite the potential and the benefits of AI in component repair, its practical applications in the remanufacturing industry have not been widely reported. The integration of AI in AM repair should be able to provide an intelligent platform for the remanufacturing industry, but its implementation will certainly require an in-depth study to counter upcoming challenges in identifying requirements, for example, the right setting of process parameters for various conditions of the incoming cores. Incoming cores have different modes of failure, severity of damages and occurrences of damage at different locations of parts or components. Verifying the quality of reparation is also crucial for the system because remanufactured components have to be returned to a ‘like-new’ condition. Through algorithms and enablers such as sensors, failures or damages of incoming cores can be diagnosed, and the quality of repaired components can be ascertained effectively.

To date, AI has found widespread applications in the diagnosis, prediction and detection of failures or damages in parts and components. Knowledge-based techniques such as fuzzy inferencing and CBR when hybridised with learning algorithms such as neural network and deep learning will certainly provide an intelligent system based on ML. The system should be able to assist in design optimisation for different component failures and damages to be repaired using AM. Genetic algorithms and other more recent optimisation techniques such as particle swarm optimisation and ant colony optimisation can be deployed to optimise design parameters for efficient, effective repair. Moreover, a hybrid system should be able to offer a better replication of human thinking and decision making for design optimisation through ML.

The development of an intelligent system for component repair will require human knowledge and experience related to component failures, design and geometry, materials and repair processes. These knowledge and heuristics must be acquired from the so-called experts to ensure that the system will successfully automate the repair process not only in terms of effectiveness but also cost efficiency. Whilst the acquisition cost of AM technology capable for repair is still high, cost–benefit analysis must be carefully considered to ensure return on investment.

Whilst recent literature has reported on process system capabilities of advanced AM technologies for component repair, limited reports have focused on the design aspects of high-value remanufacturable components that can be repaired using the AM technologies. AM technologies are highly capable of building complex shapes and lightweight structures, but ease of repair on components with complex shapes using AM has not been thoroughly addressed by researchers. Guidelines and principles on design and optimisation of components for AM manufacturing have grown exponentially over the past few years, but guidelines and principles on design and optimisation of components for AM repair are still at the nascent stage. This aspect of designing products for life cycle extension is crucial to assist the designers in ensuring their products will be repaired and restored effectively and efficiently through automated repair using AM.

Remanufacturing is one of the EoL recovery strategies of CE that can sustain natural resources by reducing raw materials and energy consumption compared with the production of a new product. Remanufacturing is responsible for extending the life cycle of products by returning them to their original specifications and warranty. The review shows that automation of repair using AM can improve efficiency and overcome issues related to conventional repair, such as dependency on skilled workers and issues related to inconsistency in the output quality. Since EoL component repair for remanufacturing is highly dependent on human judgement and decision-making, it is necessary for the automated system to be integrated with AI capabilities. Knowledge-oriented techniques of AI can be used in the acquisition and optimisation of knowledge and heuristics from highly skilled and experienced workers. Such knowledge does not only support process optimisation in repair and restoration but also optimisation and improvement to product design in order to support the efficiency and effectiveness of the repair process. Thus, AI play a remarkable role in supporting automated repair and restoration achieve the principles of CE to extend the life cycle of products. The outcomes of this review are also expected to broaden research in the field of Design for Additive Manufacturing Repair, which has a direct contribution to the implementation of CE.

Funding Statement

The authors received funding from the Konsortium Kecemerlangan Penyelidikan (JPT(BKPI)1000/016/018/25(72)), provided by the Ministry of Higher Education of Malaysia. The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript.

Additional Information and Declarations

Competing interests.

The authors declare there are no competing interests.

Author Contributions

Siti Syahara Mad Yusoh conceived and designed the experiments, performed the experiments, analyzed the data, prepared figures and/or tables, authored or reviewed drafts of the paper, and approved the final draft.

Dzuraidah Abd Wahab, Hiyam Adil Habeeb and Abdul Hadi Azman conceived and designed the experiments, performed the experiments, analyzed the data, authored or reviewed drafts of the paper, and approved the final draft.

The following information was supplied relating to ethical approvals (i.e., approving body and any reference numbers):

Ministry of Higher Education of Malaysia approved the study (JPT(BKPI)1000/016/018/25(72)).

Data Availability

The following information was supplied regarding data availability:

There are no raw data involved in this study.

- Afrinaldi et al. (2017). Afrinaldi F, Liu Z, Taufik, Zhang HC, Hasan A. The advantages of remanufacturing from the perspective of eco-efficiency analysis: a case study. Procedia CIRP. 2017;61:223–228. doi: 10.1016/j.procir.2016.11.161. [ DOI ] [ Google Scholar ]

- Akinode & Oloruntoba (2020). Akinode JL, Oloruntoba SA. Artificial intelligence in the transition to circular economy. American Journal of Engineering Research (AJER) 2020;9:185–190. [ Google Scholar ]

- Al Handawi et al. (2020). Al Handawi K, Andersson P, Panarotto M, Isaksson O, Kokkolaras M. Scalable set-based design optimization and remanufacturing for meeting changing requirements. Journal of Mechanical Design. 2020;143:021702. doi: 10.1115/1.4047908. [ DOI ] [ Google Scholar ]

- Amelia et al. (2009). Amelia L, Wahab DA, Che Haron CH, Muhamad N, Azhari CH. Initiating automotive component reuse in Malaysia. Journal of Cleaner Production. 2009;17(17):1572–1579. doi: 10.1016/j.jclepro.2009.06.011. [ DOI ] [ Google Scholar ]

- Andrew-Munot & Ibrahim (2014). Andrew-Munot M, Ibrahim RN. Remanufacturing process and its challenges. Journal of Mechanical Engineering and Sciences. 2014;4:488–495. [ Google Scholar ]